Rigging vs. Dogging | The 2026 Career Roadmap to Earning Top Dollar

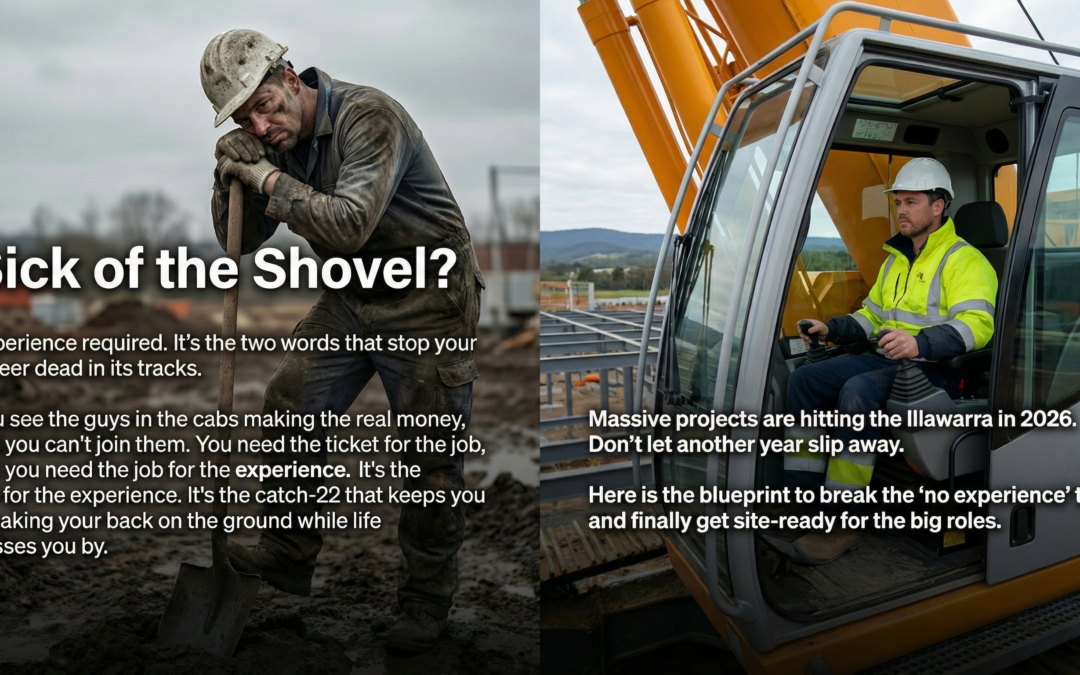

If you have spent a few months on a construction site in the Illawarra, you have probably noticed a hierarchy. There are the laborers, there are the trades, and then there are the Riggers.

Rigging is often viewed as the “Dark Art” of the construction world. While the Dogman directs the crane, the Rigger is the one calculating the impossible, erecting the steel skeleton of the building, and moving plant equipment that weighs more than a house.

As we head into 2026, with major industrial projects like the BlueScope transformation and the Shoalhaven Hospital redevelopment ramping up, the demand for dual-ticketed (Dogging + Rigging) operators is skyrocketing.

But for those just starting out, the terminology can be confusing. What is the difference between Dogging and Rigging? Do you need one to get the other? And most importantly, which one pays more?

In this guide, we map out the complete pathway from “Green” to “Advanced Rigger,” with specific dates for our January 2026 intakes at Unanderra.

The Foundation: It All Starts with Dogging (DG)

You cannot build a house without a slab, and you cannot become a Rigger without first being a Dogman.

The Licence to Perform Dogging (CPCCLDG3001) is the prerequisite for all Rigging courses.

-

The Rule: You must hold a current DG ticket (or be enrolled in the course) before you can sit the Basic Rigging course.

-

The Logic: Rigging involves complex lifting. If you don’t know how to select a sling or direct a crane (which you learn in Dogging), you aren’t safe to start erecting steel.

Pro Tip: If you are completely new, we recommend booking our Dogging course

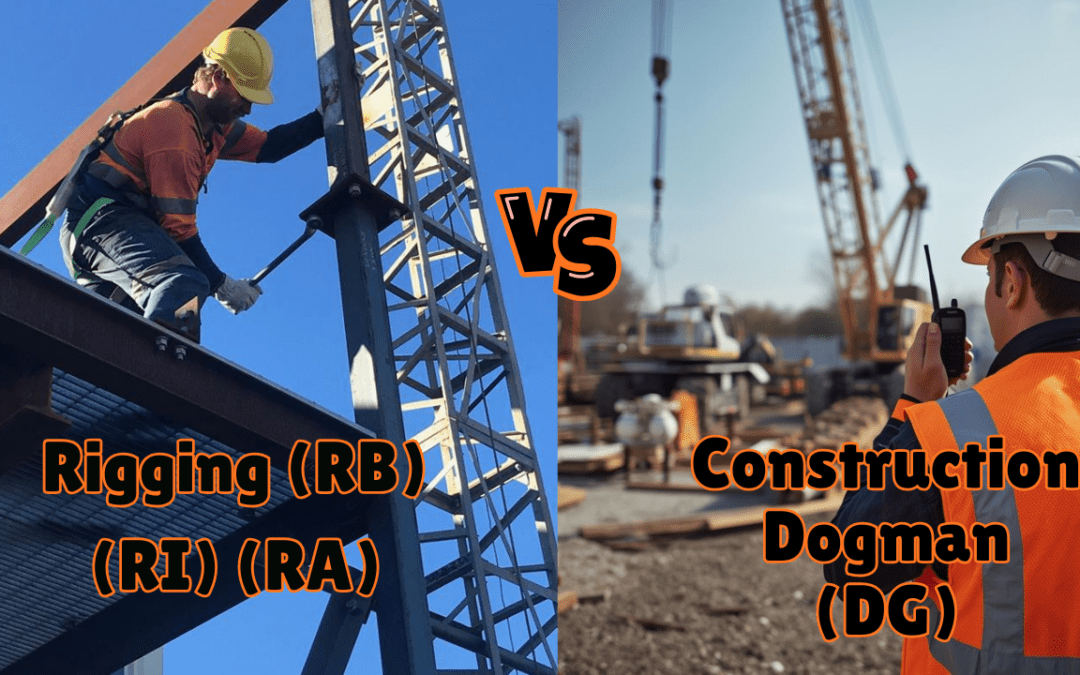

Level 1: Basic Rigging (RB) – The Steel Erector

Once you have your Dogging ticket, the next step is Basic Rigging (CPCCLRG3001). This is the “bread and butter” ticket for general construction.

What You Learn: While Dogging is about moving loads, Basic Rigging is about securing and assembling them.

- Steel Erection: You will learn how to bolt together structural steel columns and beams. This is the core skill for working on high-rise buildings and industrial sheds.

- Cantilevered Crane Loading Platforms (CCLP): Those platforms you see sticking out of skyscrapers to land materials? You learn to install them.

- Winches & Gin Poles: Old school skills that are still vital when a crane can’t reach the area.

The Job Market: With an RB ticket, you stop being just a “hook hand” and become a steel erector. This instantly makes you more valuable to structural steel companies and general builders in the Illawarra.

Level 2: Intermediate Rigging (RI) – The Heavy Lifter

This is where the boys are separated from the men. Intermediate Rigging (CPCCLRG3002) takes you away from simple steel erection and into complex, heavy lifts.

The Core Skills:

-

Dual Crane Lifts: Lifting a load with two cranes simultaneously. This requires precise calculation and coordination.

-

Tilt-Up Panels: This is huge in commercial warehousing (like the new logistics hubs in Kembla Grange). You learn to safely rotate and stand up massive concrete wall panels.

-

Demolition Rigging: Safely dismantling structures.

Why Get It? If you want to work on major industrial shutdowns or mine sites, RI is often the minimum standard. It shows you can handle “non-standard” lifts.

Level 3: Advanced Rigging (RA) – The Specialist

The Advanced Rigging (CPCCLRG4001) ticket is the PhD of the lifting world. It covers specialised equipment that terrifies most normal people.

The Core Skills:

-

Hung Scaffolds & Suspended Stages: rigging platforms that hang from the building rather than standing on the ground.

-

Gin Poles & Shear Legs: Complex leverage systems used when cranes are not an option.

This ticket is essential for anyone wanting to work in specialised maintenance, bridge building, or high-rise facade installation.

The “Combo” Strategy: How to Fast-Track Your Income

In 2026, the smartest operators aren’t just doing one course at a time with six months in between. They are doing “Block Training.”

By completing your Dogging and Basic Rigging back-to-back at AOTA, you enter the workforce as a “Dual Ticketed” operator.

Why Employers Love This:

-

You can sling the load (Dogging).

-

You can bolt it up (Rigging).

-

You are useful 100% of the time, not just when the hook is down.

Bonus: The C6 Crane Ticket

For those who want to get off the ground and into the seat, the Slewing Mobile Crane (up to 60 tonnes) – TLILIC0023 is the logical next step.

Being a Rigger who can also jump in the crane seat when needed makes you “unfireable” on many crews.

Train with the Best in the Illawarra

At AOTA, our Unanderra facility is set up for high-risk work. We don’t just read from a textbook.

-

Real Cranes: We train on real slewing mobile cranes, not simulators.

-

Real Steel: You will erect actual steel structures during your RB assessment.

-

Real Experience: Our trainers have worked on the biggest shutdowns and construction projects in Australia.

Don’t spend 2026 wondering “what if.” Get the ticket, get the skills, and get the pay rate you deserve

Ready to unlock your full potential? Explore our available courses further to discover the perfect training path for you. Or, if you have any questions or need personalised guidance, don’t hesitate to contact us. Our friendly team is here to support you every step of the way.

Remember, your dream career is within reach. With AOTA by your side, you can build the skills, confidence, and qualifications you need to succeed. So, take the first step today and start building your future!

Dedicated to your success

Nigel

Know the Risk | Interactive Hazard Finder

From high-risk zones to hidden hazards, this interactive tool helps you identify worksite dangers and shows you the safety training to tackle them confidently.