Rigging is a great career choice

So you’re looking to be a rigger? In all seriousness, if you’re reading this, it’s probably because you are interested in becoming a rigger and your first step is to research the career. Everything from Bing and Google has shown that the field is growing, with many openings and opportunities for advancement. However, I am putting my own spin on it. I’ve searched for hours about rigging before I got my foot in the door, so I feel like I could shed some valuable insight onto your research.

What is rigging?

So, what is it? Rigging is the act of moving, securing or putting down a load, while using the appropriate mechanical shifting equipment. It also involves erecting and dismantling cranes and hoists. To move a load, riggers use equipment like cranes and hoists or other machinery like chain blocks and winch systems.

Rigging is an important part of any industry that works with heavy loads. It’s used to move goods around warehouses, factories, factory relocations, construction sites and ships, as well as in mining operations, oil rigs and military operations, agriculture, and environmental applications, abnormal and heavy loads moved for the food and dairy sector, steel erection and dismantlement.

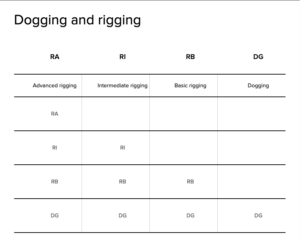

What Types of Rigging Qualifications Are There?

Basic (RB), Consists of dogging and rigging work involving:

movement of plant and equipment

steel erection

hoists (including mast climbing hoists)

placement of precast concrete

safety nets and static lines

perimeter safety screens and shutters

cantilevered crane loading platforms

Intermediate (RI) Consists of all basic rigging work plus rigging involving:

cranes, conveyors, dredges and excavators

tilt slabs

hoists with jibs and self climbing hoists

demolition

dual lifts

But excluding rigging work involving equipment listed below under Advanced rigging.

Advanced (RA). Advanced rigging – consists of all intermediate rigging work plus rigging that involves:

gin poles and shear legs

flying foxes and cableways

guyed derricks and structures

suspended and fabricated hung scaffolds

Also Read “A Guide To High Risk Licensing”

What Are Some of the Skills A Riggers Needs?

To ensure success as a rigger, you should have in-depth knowledge of rigging equipment, excellent spatial awareness, and good communication skills. A skilled rigger is meticulous with construction and always aware of safety on the construction site.

Good communication skills are important for a rigger to make sure that all parts of the rigging work together smoothly. Riggers must also be able to use their math skills to calculate measurements and angles for the correct placement of equipment. Riggers must also have excellent spatial awareness because they need to know how each piece fits together and where it needs to go on the construction site.

Riggers need to be able to read blueprints and drawings so they can determine how different pieces of equipment will fit together before they go out onto the job site. They must also understand how different types of materials will react under certain conditions so they can ensure that everything stays safe throughout the project’s duration.

Rigging in Manufacturing

Rigging in the manufacturing industry is a crucial part of the process. It allows manufacturers to bring their products to life, and it can help them achieve greater success.

There are many benefits to using rigging techniques in manufacturing:

- It makes it easier to move parts around during assembly

- It helps prevent damage to equipment

- It makes it easier for workers to access dangerous areas without having to climb ladders or scaffold structures themselves.

What is rigging in civil engineering?

Rigging is used in many industrial settings, but it’s also an important part of civil engineering projects.

For example, when constructing a building or bridge, rigging is used to raise materials into place. It’s also used for site preparation and for moving heavy equipment around on job sites. Riggers are responsible for planning out how to use rigging to accomplish these tasks safely and effectively.

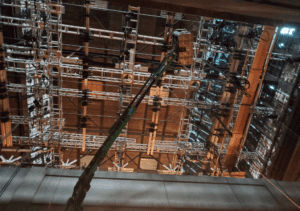

What Is Rigging in Construction

On construction and building sites, a rigger is an essential part of the team. On construction sites, rigging provides the means to safely lift and move heavy beams or frames, or move equipment up multiple floors. Everything from power tools to large HVAC systems can be moved into place with the correct method of rigging. Riggers are trained to calculate weight, suspension, and balance. They can control the movements of the items being moved through tight spaces or great heights.

The job of a rigger is not easy. It requires extensive training and experience working with other workers on a construction site. It also requires a lot of physical strength because many items will need to be lifted by hand into place by the rigger himself or herself. This type of work is typically done by men but women can also become riggers if they have the right skills and training necessary for this type of work environment.

Why is rigging important in the construction industry?

Rigging systems are important in the construction industry because they ensure the safety of everyone on a construction site.

- Rigging systems are used to support, lift and move heavy materials. They can be used to suspend scaffolding from tall structures or to lower heavy items down from great heights.

- Rigging systems allow for construction workers to work in safety, which reduces their risk of injury or death.

- Rigging systems also help prevent damage to property by ensuring that materials don’t fall down onto people or vehicles below them.

- Rigging systems ensure the safety of everyone on a construction site.

What is rigging in logistics?

Rigging is the equipment used to support and move loads with cranes, derricks and other lifting equipment. Rigging is used to raise or lower the load as well as support it during transportation or installation.

In material handling systems, rigging is designed to lift loads from one floor level to another or from one level of a structure to another. It can also be used in underwater lifting operations where long cables are attached to a load using a buoyancy device such as a lifting bag.

Rigging in the mining industry

Rigging is the process of securing a mine’s equipment in place. It’s used to prevent equipment from moving during mining operations, as well as to make sure that the equipment is safe from damage from other parts of the mine.

In mining, rigging is often done with ropes or cables, which are attached to a single point at the center of gravity for each piece of equipment. The cables are then secured to another point on the ground or a wall with anchors.

Rigging is an important part of mining because it keeps workers safe and prevents damage to equipment by preventing them from moving around while they’re in use.

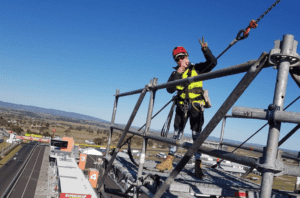

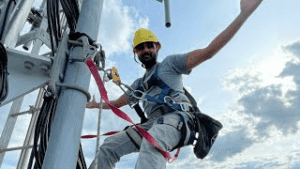

Rigging in Telecommunications

Rigging in telecommunications is a career path that is growing with the technology industry. The job of a rigger is to set up the equipment and make sure it stays in place. This includes, but is not limited to:

- Wires, cables and fiber optics

- Antennas, microwave dishes and satellite dishes

- Other structural components such as towers, poles and buildings

What Does a Rigger Do In Movies?

On movie sets, a rigger plays a different role than riggers on construction sites. A rigger in movies will also use ropes, pulleys, and chains to move heavy items, but those heavy items are expensive camera equipment, lighting, or set pieces. Riggers on movie sets will build scaffolding to hoist lights and support cameras for different angles shots. They will sometimes use their rigging to move actors, creating the appearance of flying or falling. A rigger’s work can be complicated and dangerous—they are responsible for keeping everything safe so that the actors can perform without injury. In addition to constructing scaffolding, they may also tie off cables from the scaffolding so that if someone falls off of it they don’t fall too far and injure themselves.

What is rigging in stage work?

The job of the rigging crew is to install all the cable and distribution equipment so that the large amounts of electricity needed for production can flow safely from the power source to the lights all over the sound stage or practical location.

The rigging crew is responsible for making sure that all of these cables are installed correctly. They work with electricians, who are responsible for installing lighting and other electrical equipment, as well as with set dressers who design how everything looks on screen. They also work with prop masters and art directors to make sure that the rigging equipment blends in with everything else on set.

The skills needed to be a rigger are the same for any industry. Even though it is a specialized field, riggers can use their skills in a variety of industries, such as entertainment, construction, and transportation. Riggers must follow strict safety procedures and protocols in order to keep everyone safe at all times.

How Do You Become a Rigger?

Rigging involves a combination of theory, practical hands-on experience and the use of modern rigging software for calculating load capacities and risk assessments. To become a certified rigger you will need to complete a formal course, from a Registered Training Organisation (RTO).

So let’s wrap up. Now you know what’s involved to become a rigger and be successful at the job. First, let me tell you that the road to becoming a rigging contractor is not an easy one, but it can be done if you’re willing to work hard and be smart about it. Remember that strong work ethic, focus and determination are crucial as you will face many challenges along the way. It’s never too late to learn or improve on building your reputation of being a great rigger. Reaching out to people in your network and learning from them could help you stack up well for your future endeavors. To become successful in your career as a rigger, networking skills are essential.

The flexibility and versatility of being a rigger can also lead to many great opportunities for advancement. While some riggers choose to stay in the field, others go on to become supervisors, engineers, or program managers in their specific industry.

Need to know more? All Course Enquiries

Dedicated to your future success

Nigel